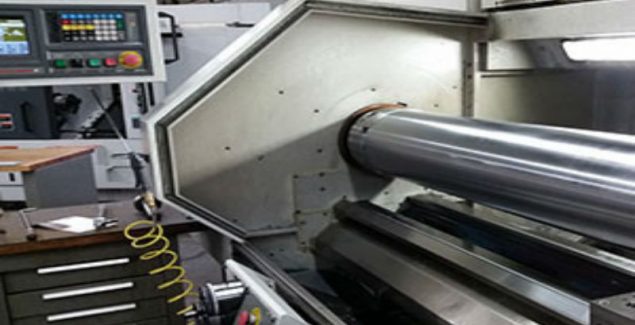

During the manufacturing of a system or product, there is likely to be the need for some level of machine metal services. These services involve taking metal of all types and turning it into specific parts and components. The machining process is difficult and...