In many industries today, hardfacing or hard surfacing is common practice. It can restore many parts and enhance their performance too. But which hardfacing rods are best to use? Let's check out the practice a little closer to help you determine the best course of...

Metal

Latest Articles

- When To Hire An Employee Engagement Speaker

- When Should A Business Implement Virtual Sales Training For Sales Reps

- Cleaning Made Simple With Power Washers Accessories That Tackle Tough USA Jobs Fast

- Supportive solutions for families seeking Autism Services Miami FL with compassionate care

- Experience Lasting Smoothness At A Waxing Salon In Leander TX Residents Rely On For Results

Categories

- Accident Attorney (3)

- Accident Injury (2)

- Accident Injury Attorney (5)

- Accident Lawyer (10)

- Accountants (5)

- Accounting (17)

- Addiction Treatment (3)

- Addiction Treatment Center (1)

- Adhesives (1)

- Adoption (5)

- Adventure and Sports (1)

- Advertising & Marketing Agency (1)

- Agriculture and Forestry (6)

- Air Conditioner (5)

- Air Conditioning (48)

- Air Conditioning & Heating (18)

- Air Heating & Conditioning (8)

- Aircraft Cargo Loaders (1)

- Aircraft Simulation (1)

- Airport Shuttle Service (2)

- Alarm System (6)

- Alarm Systems (3)

- Allergies (9)

- Aluminium (6)

- Aluminium|aluminum (1)

- aluminum (5)

- Aluminum Supplier (6)

- Ambulance Service (1)

- Anatomy Models (1)

- Animal (7)

- Animal hospital (40)

- Animal Removal (8)

- Animals (3)

- Antiques and Collectibles (6)

- Apartments (3)

- Appliance Repair (7)

- Appliance Repair Service (3)

- Appliances (11)

- Appraisal (2)

- Apps (1)

- Arborist Supplies (6)

- Architect (2)

- Archives (1)

- Art Galleries (1)

- Art Supplies (1)

- Arts (5)

- Arts and Entertainment (24)

- Arts Gallery & Entertainment (2)

- Asian Restaurants (1)

- Asphalt Contractor (18)

- Assembly (2)

- Assisted Living (48)

- Attorney (50)

- Attorneys (9)

- Authorized Retailers (2)

- Auto (4)

- Auto Accident Attorney (5)

- Auto Body Shop (4)

- Auto Engine Rebuilding (3)

- Auto Insurance (2)

- Auto Loans (1)

- Auto Parts Store (11)

- Auto Repair Shop (37)

- Automobile (10)

- Automobiles (16)

- Automotive (145)

- Autos (6)

- Autos Repair (23)

- Avionics Interface Hardware (1)

- Awards & Gifts (7)

- Ayurvedic Centre (3)

- Baby Food (1)

- Bail Bond (3)

- Bail Bond Service (1)

- Bank (1)

- Bankruptcy Attorney (4)

- Bankruptcy Law (11)

- Banners (1)

- Barbecue & Fire Pits (1)

- Bars and Restaurant (1)

- Bathroom Remodeling (1)

- Bathroom Renovation (1)

- Bearing Supplier (1)

- Beauty (17)

- Beauty and Cosmetic Services (4)

- Beauty Salon (6)

- Bed & Mattresses (2)

- Bedroom (2)

- belts (2)

- Beverages (6)

- Bicycle Shop (1)

- Boat Manufacturers (2)

- Boat Rental Service (1)

- Boat Trailer Dealer (3)

- Boat Trailers (7)

- Bonds (2)

- Book Writer (1)

- Brewery Equipment (3)

- Brewhouse (3)

- Bronze Metals & Alloys (1)

- Building Supplies (1)

- Business (386)

- Business & Investment (46)

- Business and Economy (5)

- Business Management Consultant (2)

- business services (90)

- Business|Business Services (3)

- Business|Health & Medical (1)

- Cabinetry (4)

- Caffeinated Snacks (2)

- cake decorating (1)

- cakes (1)

- Call Center (5)

- Camera Store (1)

- Camp (1)

- Camping (2)

- Cancer Treatment Center (2)

- Candle store (1)

- Candy Store (2)

- canopies (1)

- Car Dealer (8)

- Car Insurance (2)

- Car Repair and Maintenance (2)

- Car Service (6)

- Carbon Supplier (3)

- Cardiology Equipment (1)

- Careers & Jobs (2)

- Careers & Recruitment (1)

- Carpet & Flooring (1)

- Carpet Cleaner (2)

- Carpet Cleaning (1)

- Carpet Cleaning Service (1)

- Carpet Store (2)

- Carpets (6)

- Casino Theme Party (6)

- Catering (3)

- cattle (1)

- Child Care (3)

- Chimney (16)

- Chimney Sweep (5)

- Chiropractic (29)

- Chiropractic Care (1)

- Chiropractic Clinic (1)

- Chiropractor (8)

- Christian Church (1)

- Church (3)

- Cigar Shop (6)

- Cleaning (15)

- Cleaning Service (12)

- Cleaning Services (17)

- Clothing (13)

- CNC Machine Shop (6)

- Coating (1)

- Coins (1)

- Commercial & Industrial Equipment Supplier (4)

- Communication (1)

- Communication & Technology (2)

- communication skill (1)

- Compost (5)

- Compressor (1)

- Computer & Internet (11)

- Computer Security Service (1)

- Computers (12)

- Concrete Contractor (6)

- Construction (7)

- Construction & Remodeling (4)

- Construction and Maintenance (242)

- Construction Equipment (1)

- Consulting (3)

- Consumer Goods & Services (2)

- Consumer Goods and Services (1)

- Contract Manufacturing (5)

- Contratctor (4)

- Convenience Stores (8)

- Cooling (2)

- Corrugated Box Manufacturer (1)

- Cosmetic Medicine (2)

- Cosmetology (15)

- Cottages (2)

- Counseling Services (2)

- Counselor (1)

- Countertops (1)

- courier (4)

- Cranes & Hoists (1)

- Credit Card Processing (1)

- Cremation (34)

- Crime scene clean up (2)

- Criminal Lawyer (2)

- Cruise Line Company (1)

- Custom Home Builder (5)

- Custom Labs (1)

- custom products (4)

- Cutting and Machining (1)

- Dance School (9)

- Data Communications (1)

- Data Entry Services (5)

- Data Recovery Service (1)

- Dating (7)

- Day Spa (1)

- Demolition (4)

- Dental (27)

- Dental Care (11)

- Dental Implants (5)

- Dental Services (20)

- Dentist (264)

- Dermatology (7)

- Diesel Fuel Supplier (2)

- Digital Printing (12)

- Distributors & Fabricators (3)

- Divorce Lawyer (3)

- Doctor (2)

- Document Shredding (6)

- Dog Day Care Center (7)

- Dog Daycare (4)

- Dog trainer (1)

- Door Installation (1)

- Door Manufacturer (3)

- Doors & Windows (18)

- Doors and Windows (10)

- Drug Addiction Treatment Center (7)

- Duct Cleaning (1)

- E-COMMERCE SERVICE (1)

- eclipse (3)

- Education (33)

- Education & Colleges (54)

- Electric Service (5)

- Electrical (17)

- Electrical|Health & Medical (1)

- Electrician (32)

- Electrician|Electronics Manufacturer (1)

- Electronic Cigarettes (3)

- Electronics & Electrical (1)

- Electronics and Electrical (23)

- Electronics Manufacturer (8)

- Electronics Store (1)

- Elevator Maintenance Services (1)

- Emergency Clean-up Services (1)

- Emigration and Immigration (1)

- Employment Agency (2)

- Energy (2)

- Engineering (3)

- Engineering Consultant (1)

- Environment (1)

- Equipment and Supplies (5)

- Estate Planning and Probate (2)

- Event Planner (2)

- Event Planning (14)

- Event Venue (5)

- Excavator Attachments Manufacturer (1)

- Explosives (1)

- Eye Care (17)

- Eye Care Center (4)

- Eye Doctor (9)

- Eye Doctors (2)

- Eyeglasses (13)

- Facial Spa (1)

- Family (1)

- Family Law Attorney (1)

- Family Medicine (1)

- Family Planning Center (1)

- Family Practice Physician (1)

- Farm Equipment Supplier (3)

- Feeders (4)

- Fence Contractor (17)

- Fences and Gates (2)

- Fertilizer Supplier (1)

- Film and Tinting (5)

- Finance (15)

- Finance & Money (9)

- Financial Services (44)

- Fire Alarm Supplier (2)

- Fire and Security (11)

- Fire Damage (2)

- Fire Places and Stoves (1)

- Fire Protection Service (2)

- Firearms Academy (1)

- Fireplace Store (6)

- Fireplaces (14)

- Fitness (2)

- Fitness and Conditioning (10)

- Fitness Training Center (15)

- Flooring (27)

- Flooring services (4)

- Florist (3)

- Florists (4)

- Flowers (1)

- Food (42)

- Food & Beverages (1)

- Food & Related Products (6)

- Food And Related Products (1)

- Food Distributor (1)

- Food Franchise (1)

- Ford Dealer (2)

- Foreclosure (1)

- Foreclosures (1)

- Foundation Repair (24)

- Franchise Broker (1)

- Fruitcake (3)

- Fundraising (1)

- Funeral Services (23)

- Furniture (26)

- Furniture Store (4)

- Furniture Stores (1)

- Garage (4)

- Garage Door (11)

- Garage Door Supplier (9)

- Garage Door Supplier|Garage Doors (1)

- Garage Doors (2)

- Gardening (1)

- Gas & Chemical Service (5)

- Gas Station (1)

- General Contractor (1)

- Gift Shop (3)

- Gifts Shops (4)

- Glass (10)

- Glass & Window Repair (11)

- Glass Repair (3)

- Gold (9)

- Gold & Silver (1)

- Gold & Silver Wholesaler (1)

- Golf Cart Dealer (2)

- Granite Supplier (1)

- Graphic Designer (7)

- Graphite Distributor (1)

- Guard and Patrol (1)

- Guns (17)

- Gutter Protection Systems (6)

- Gutter Repair (3)

- Gymnastics (6)

- Gynecologist (1)

- Hair Care (2)

- Hair Salon (1)

- Hardware (3)

- Harley-Davidson (2)

- Head Shops (2)

- Health (130)

- Health & Beauty (5)

- Health & Fitness (2)

- Health & Medical (112)

- Health Care (5)

- Health/Wellness (1)

- Healthcare (137)

- Healthcare Administrator (2)

- Healthcare|Veterinary (1)

- Heat Treatment (1)

- Heating (10)

- Heating and Air Conditioning (91)

- Heating and Cooling (10)

- Heating Contractor (6)

- Heating Oil Supplier (1)

- Home (4)

- Home & Garden (11)

- Home and Garden (42)

- Home and Garden|Landscaping (1)

- Home Appliances (2)

- Home Builders (3)

- Home Contractor (2)

- Home Health Care Service (18)

- Home Improvement (148)

- Home Insurance (1)

- Home Remodeling (7)

- Home Security System (2)

- Home Theater (1)

- Homeowners Insurance (1)

- Homes (1)

- hosting (4)

- Hotel (1)

- Hotels & Motels (2)

- Hotels & Restaurants (3)

- House Cleaning Service (8)

- Housekeeping (1)

- Human Resource Consulting (3)

- Human Resources (2)

- HVAC (9)

- HVAC Contractor (42)

- HVAC Contractors (6)

- Hydraulic (1)

- Hydraulic Equipment Supplier (5)

- Ice Cube (13)

- Imaging Centers (1)

- Indoor & Outdoor Digital Displays (1)

- industrial (5)

- Industrial And Construction Supply Distributor (1)

- Industrial Automation (4)

- Industrial Contractors (3)

- Industrial Equipment (2)

- Industrial Goods and Services (43)

- Industrial Supplier (9)

- Industrial Supplies (2)

- Industrial Supply (11)

- Industries (3)

- industry (4)

- Information Technology and Services (1)

- Injection Molding (4)

- Injury Attorneys (2)

- Installation (1)

- Insulation (2)

- Insurance (127)

- Insurance Agency (3)

- Insurance Company (7)

- Intercom Systems (2)

- Interior Building Systems (2)

- Interior Decoration (2)

- Interior Designer (11)

- Internet Marketing (4)

- Internet Marketing Service (10)

- Internet Providers (4)

- Investment (3)

- Investment Services (3)

- irrigation services (1)

- IT Company (3)

- IT Services (2)

- IT Solution (2)

- IV Therapy (1)

- Janitorial Cleaning Services (1)

- Jeweler (2)

- Jewellery (9)

- Jewelry (32)

- Jewelry Boxes (2)

- Job Interview Coaching Services (1)

- Kids and Teens (2)

- Kitchen cleaning (6)

- Kitchen Renovation (4)

- Laboratory Equipment (9)

- Laboratory Equipments (4)

- Lamp Store (3)

- Lamps (2)

- Land Surveyor (2)

- Landscape Contractors (4)

- Landscape Lighting Designer (3)

- Landscape Supply (2)

- Landscaper (3)

- Landscaping (68)

- Lasers (9)

- Laundry Service (1)

- Law (55)

- Law & Legal (24)

- Law & Politics (1)

- Law Firm (17)

- Law Schools (3)

- Law|Lawyers (1)

- Lawn Care Service (8)

- lawns (1)

- Lawyers (346)

- Lawyers and Law Firm (15)

- Lawyers and Law Firms (17)

- Lead Products (1)

- Leak Detection (1)

- Led (3)

- Led Digital Billboards (1)

- Legal Service (17)

- Legal Services (6)

- Lifestyle & Relationships (3)

- lighting (2)

- Lighting Designers and Suppliers (2)

- Lighting Store (1)

- Limousine Service (2)

- Livestock (2)

- Loans (6)

- Locksmith (15)

- Locksmithing (3)

- Locksmiths (8)

- Log Cutting Equipment (4)

- Machine (9)

- Machine Shop (2)

- Machinery and Tools (6)

- Machinery Tools (10)

- Machining (4)

- Machining Manufacturer (4)

- Makeup Products (2)

- Mammography Service (1)

- Manufacturing (3)

- Marble Supplier (2)

- Marketing and Advertising (1)

- Martial Arts Products (4)

- Martial Arts School (2)

- Masonry Supply Store (2)

- Massage Therapy (10)

- Matchmaking (1)

- Mattress Store (3)

- Mattresses (2)

- Media Production (2)

- Medical Center (5)

- Medical Clinic (4)

- Medical Company (1)

- Medical Device (3)

- Medical Equipment (7)

- Medical Spa (10)

- Medical Supply (5)

- Medical Supply Store (1)

- Medications (1)

- Mediterranean Restaurant (2)

- Mediterranean Restaurant|Restaurant (1)

- Mental Health Service (2)

- Menu (1)

- Menus (1)

- Messaging Services (4)

- Metal (15)

- Metal Distributors (2)

- Metal Fabricators (11)

- Metal Finishing (1)

- Metal Heat Treating Service (2)

- Metals (20)

- Meters and Metering (4)

- Mobile Business Card (1)

- Mobile Home Dealer (2)

- Mobile Phone Repair Services (3)

- Molding (4)

- Molding Manufacturers (1)

- Molding Supplier (1)

- Money Transfers (1)

- Monument (2)

- Mortgage (1)

- Motivational Speaker (2)

- Motorcycle Dealer (1)

- Motorcycles (2)

- Mover (11)

- Moving (134)

- Moving and Relocating (15)

- Moving and Storage (5)

- Moving Companies (31)

- Moving Services (46)

- Music (3)

- Music Instruments (1)

- Music School (2)

- Natural Foods Store (2)

- Nose and Throat (2)

- Occupational Medical Physician (1)

- Office Products (6)

- Office Solutions (1)

- Office Storage (1)

- Oil and Gas (17)

- Oil Change Service (1)

- Oil Field Equipment Supplier (1)

- Optometrist (9)

- Orthopedic Surgeon (1)

- Outdoors (1)

- Overhead Doors (1)

- Packaging (11)

- Packaging Supply Store (1)

- Pain Management (1)

- pain management services (1)

- Painting (7)

- Painting & Sandblasting (2)

- Painting Company (1)

- Painting Services (19)

- Park Models (6)

- Parking (1)

- Parts & Accessories (1)

- Parts and Spares (1)

- Party Planner (2)

- Party Supplies (2)

- Paving (5)

- Paving Service (4)

- Pawn Shop (4)

- Pawn Shops (3)

- Personal Defense (1)

- Personal Injury (31)

- Personal Injury Attorney (6)

- Personal Trainer (2)

- Pest & Disease Control (1)

- Pest Control (49)

- Pest Control Service (24)

- Pet Boarding (4)

- Petroleum Products (13)

- Pets (13)

- Pets & Animals (17)

- Pharmaceutical Packaging (2)

- Pharmacy (6)

- Photo Shop (4)

- Photography (3)

- Physical Therapy (6)

- Pipe Products (2)

- Pipes and Fittings (1)

- Plant Nursery (1)

- Plastic Surgeon (11)

- Plating (2)

- Plating and Metal Finishing (3)

- Playground Equipment (1)

- Plumber (16)

- Plumbing (152)

- Plumbing & Fitting (1)

- Podiatry (2)

- Pool Products (3)

- Pregnancy Care Center (2)

- Preschool (1)

- Printers (2)

- Printing (12)

- Printing Services (2)

- Produce Market (1)

- Product Liability Lawyer (1)

- Propane (1)

- Property Management Company (4)

- Psychotherapist (4)

- Quarry and Aggregate Production (1)

- Radiology (3)

- Real Estate (72)

- Real Estate Attorney (6)

- Real Estate Law (2)

- Real Estate School (1)

- Record Store (1)

- Recreation (1)

- Recruiters (1)

- Recycling (9)

- Religion (1)

- Religious Center (1)

- Remodeling (16)

- Repair (1)

- Repair Services (12)

- Replacement Doors and Windows (1)

- Restaurant (34)

- Restoration (6)

- Restoration and Cleaning (2)

- Restoration Services (6)

- Retirement (3)

- Retirement Community (6)

- Reusable Bags (1)

- Rheology (3)

- Roadside Assistance (3)

- roller (4)

- Roofing (143)

- Roofing & Restoration (12)

- Roofing Contractor (27)

- Safety Equipment Supplies (6)

- Sales Coaching (5)

- sales management training (1)

- Salons (7)

- Salons and Spas (4)

- Sandwich Shop (1)

- Scale Supplier (2)

- Science & Technology (11)

- Screen printer (1)

- Scuba Tour Agency (1)

- Search Engine Optimization Firms (2)

- Security (19)

- Security Services (9)

- Security System & Services (1)

- Security System Supplier (6)

- Senior Care (7)

- SEO (4)

- Separators (6)

- Septic services (1)

- Septic System Service (12)

- Septic Tank & Portable Restrooms (1)

- Septic Tanks (24)

- Shipping (2)

- Shooting Range (1)

- Shopping (98)

- Shopping|Tobacco (1)

- Siding (2)

- Sign & Banner (2)

- Signage (8)

- Skin care (10)

- Skin Care Clinic (7)

- Smartphones (1)

- Snow Removal (3)

- Society (6)

- Software (1)

- Software Company (2)

- Software Development (4)

- Soil and Additives (4)

- Solar (6)

- Solar Panels (2)

- Spa (2)

- Speech Therapist (1)

- Sports (3)

- Sports & Games (4)

- Spraying Equipment (1)

- Sprinklers (3)

- Stainless Steel (2)

- Steel Fabricator (2)

- Steel Fabricators (1)

- Sterilization (1)

- Storage (3)

- Storage and Protection (6)

- Student Aid and Grants (1)

- Summer Camp (1)

- Sunglasses (1)

- Supply Chain Management (1)

- Surgeon (1)

- Surgeons & Clinics (3)

- Surrogacy (2)

- Swimming Pool Contractor (1)

- Swimming Pools (21)

- Swimming Pools & Spas (14)

- Swimming Pools and Spas (7)

- Tailors (4)

- Tanning Beds (1)

- Tattoo (3)

- Tattoo Shop (2)

- Tax (5)

- Taxis (3)

- Telecommunication (2)

- Telecommunications (5)

- Telecommunications Services (1)

- Theater and Drama (1)

- Therapeutic (3)

- Thermoforming (1)

- Tile and Stone (1)

- Timing Belt Manufacturer (2)

- Tires (8)

- Tobacco (1)

- Tobacco Shop (2)

- Tool Grinding Service (4)

- Tools and Equipment (8)

- Towing Service (8)

- Tractor Dealer (2)

- tractors (4)

- Trade Show Services (1)

- Training (7)

- Transformers and Inductors (1)

- Transgender Surgery (1)

- Translation Services (1)

- Transmission Shop (1)

- Transport (2)

- Transport & Logistics (7)

- Transportation (11)

- Transportation & Travel (7)

- Transportation and Logistics (29)

- Trash Removal Service (1)

- Travel (29)

- Travel and Tourism (12)

- Tree Service (9)

- Tree Services (24)

- Trips (1)

- Truck Rental (2)

- Truck Repair (5)

- umbrella (1)

- Umbrellas (1)

- Used (1)

- Used Car Dealer (1)

- Utilities (1)

- Vacation Home (1)

- Vacation Rentals (3)

- Vacuum Pumps (1)

- Valve Manufacturer (2)

- Van Rental (1)

- Vascular (1)

- Vascular Surgeon (1)

- Vehicle Warning System (2)

- Vehicles (12)

- Veterinarian (5)

- Veterinarians (19)

- Veterinary (14)

- Veterinary Medicine (1)

- Video Production (1)

- Video Streaming (5)

- VOIP (1)

- Wallpaper and Coverings (4)

- Wallpaper Store (2)

- Warehousing and Storage (1)

- Waste Management (37)

- Water Conditioning (1)

- Water Damage (3)

- Water Damage Restoration (2)

- Water Damage Restoration Service (4)

- Water Heater Installation (3)

- Water Proofing (19)

- Water Resources (2)

- Water Softening (4)

- Water softening equipment supplier (1)

- Water Sports (3)

- Water Testing (7)

- Water Treatment (8)

- Water Treatment Plant (1)

- Water Treatment Products (2)

- web design (12)

- Web Design & Development (3)

- Website Designer (9)

- Wedding & Jewellery (1)

- Wedding Photography (1)

- Wedding Planner (1)

- Wedding Service (2)

- Weddings (22)

- Weighing Scales (2)

- Weight Loss (2)

- Welding Equipment Supply Store (9)

- Well Drilling Contractor (2)

- Wheels and Tires (2)

- Wholesale & Distribution (1)

- Wildlife (3)

- Window Coverings (2)

- Window Installation (11)

- Window Installation Service (7)

- Window Tinting (1)

- Windshields and Glass (6)

- Wine (6)

- Wine Cellar (1)

- Wine Store (5)

- Wireless (2)

- Wood Products (10)

- Wooden Doors (4)

- Woodworking (1)

- Worker's Compensation (3)

- Writers (1)

- Wrongful Death Attorney (3)

- Yoga (3)

Tags

Capital-City-Nurses (13) dental implants (5) Holistic Veterinary Healing (8) lemon law (6) pest control (5)

Archives

- June 2025 (35)

- May 2025 (8)

- April 2025 (5)

- March 2025 (8)

- February 2025 (14)

- January 2025 (30)

- December 2024 (6)

- November 2024 (5)

- October 2024 (4)

- September 2024 (2)

- August 2024 (5)

- July 2024 (2)

- May 2024 (1)

- January 2024 (2)

- April 2023 (1)

- October 2022 (1)

- September 2022 (1)

- January 2019 (1)

- November 2018 (7)

- September 2018 (95)

- August 2018 (151)

- July 2018 (159)

- June 2018 (131)

- May 2018 (154)

- April 2018 (134)

- March 2018 (191)

- February 2018 (192)

- January 2018 (175)

- December 2017 (143)

- November 2017 (152)

- October 2017 (84)

- September 2017 (148)

- August 2017 (113)

- July 2017 (91)

- June 2017 (100)

- May 2017 (135)

- April 2017 (117)

- March 2017 (85)

- February 2017 (91)

- January 2017 (193)

- December 2016 (156)

- November 2016 (119)

- October 2016 (102)

- September 2016 (158)

- August 2016 (319)

- July 2016 (183)

- June 2016 (144)

- May 2016 (196)

- April 2016 (162)

- March 2016 (205)

- February 2016 (150)

- January 2016 (195)

- December 2015 (217)

- November 2015 (171)

- October 2015 (190)

- September 2015 (196)

- August 2015 (54)

- July 2015 (99)

- June 2015 (107)

- May 2015 (63)

- April 2015 (59)

- March 2015 (106)

- February 2015 (136)

- January 2015 (123)

- December 2014 (76)

- November 2014 (56)

- October 2014 (57)

- September 2014 (101)

- August 2014 (74)

- July 2014 (212)

- June 2014 (73)

- January 1970 (25)

Some Characteristics and Applications of 5052 Aluminum Sheets

by admin | Nov 8, 2016 | Metal

5052 aluminum is an alloy that provides an extensive range of design options that benefit customers in the consumer electronics industry. As a lightweight, yet high strength material, 5052 aluminum is a very useful material for a variety of applications. This type of...

One Common Kind of Stainless Steel Sheet For Sale in Pennsylvania

by admin | Nov 2, 2016 | Metal

Running a successful fabrication shop in the Keystone State can be difficult, but it can also be rewarding. Pennsylvania is still a place where hard work pays off even if the famous steel mills of the state's past are less of a factor than they used to be. Fabricators...

The Options For Heat Treating Stainless Steel

by admin | Mar 16, 2016 | Metal

There are several different options to consider for heat treating stainless steel. The specific application and the type of alloy will be major factors in determining which of the heat treatment methods are the most appropriate. Another factor that will need to be...

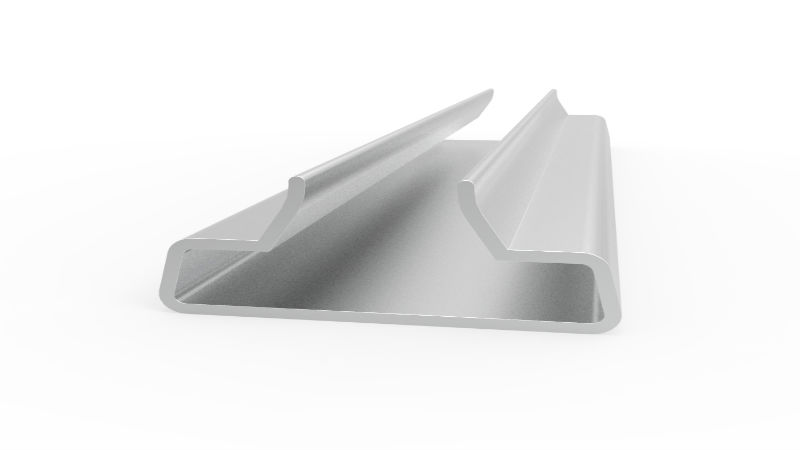

Things to Know about Metal Furring

by admin | Feb 4, 2016 | Metal

Furring materials like hat channel are used in many different commercial and residential applications today. Channel is one of the most convenient ways to mount one surface to another surface. In fact, it has many advantages over installing strips or standard studs....